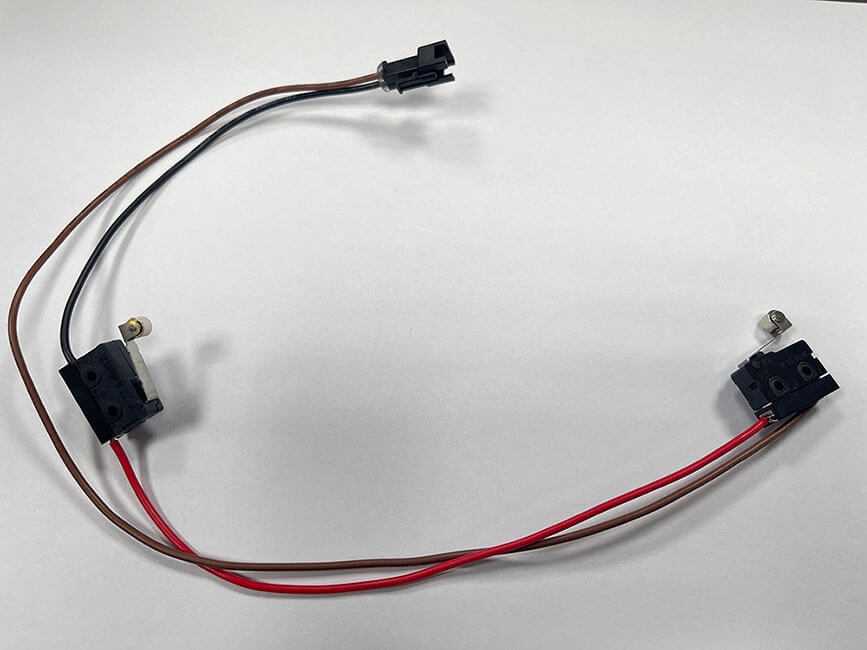

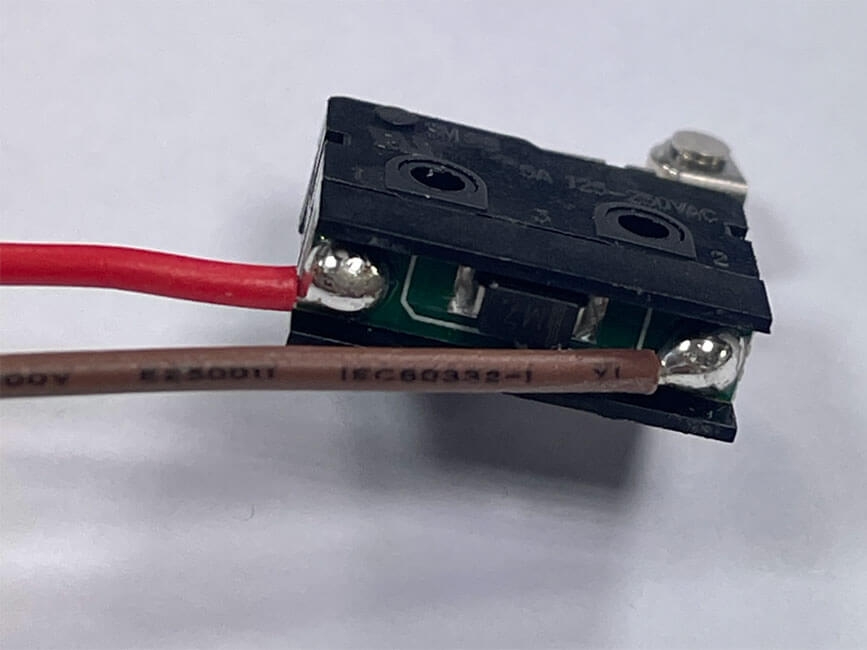

Micro Switch

Why Your Industrial Equipment Demands a Custom Micro Switch Harness Solution

Off-the-shelf switches may be adequate for a controlled office environment, but they consistently fall short on the factory floor. A reliable, industrial-grade micro switch solution proves its value across three critical applications:

- Precision Limit Detection & Positioning

On an automated production line or CNC machine, the micro switch is what defines the operational boundaries. It detects the range of motion for a robotic arm, confirms a workpiece is in position on a conveyor, or verifies the home position of a tool magazine. Chang Ming’s harnesses are engineered to ensure these split-second trigger signals are transmitted without distortion, even in factory environments with high levels of electromagnetic interference (EMI).

- Fail-Safe Industrial Safety Interlocks

Operator safety is paramount. Micro switches installed on machine guards and safety doors must instantly cut power the moment they are opened. Our harness assemblies undergo rigorous tensile and flex testing to guarantee the wiring remains secure over years of use, eliminating the risk of safety failures caused by wire fatigue.

- Process Status Verification

Is a workpiece securely held by a clamp? Is a valve open or closed? Confirmation of these process states relies on the feedback from a micro switch. We provide specialized, abrasion-resistant wiring that withstands exposure to cutting fluids and chemicals, ensuring long-term operational stability.

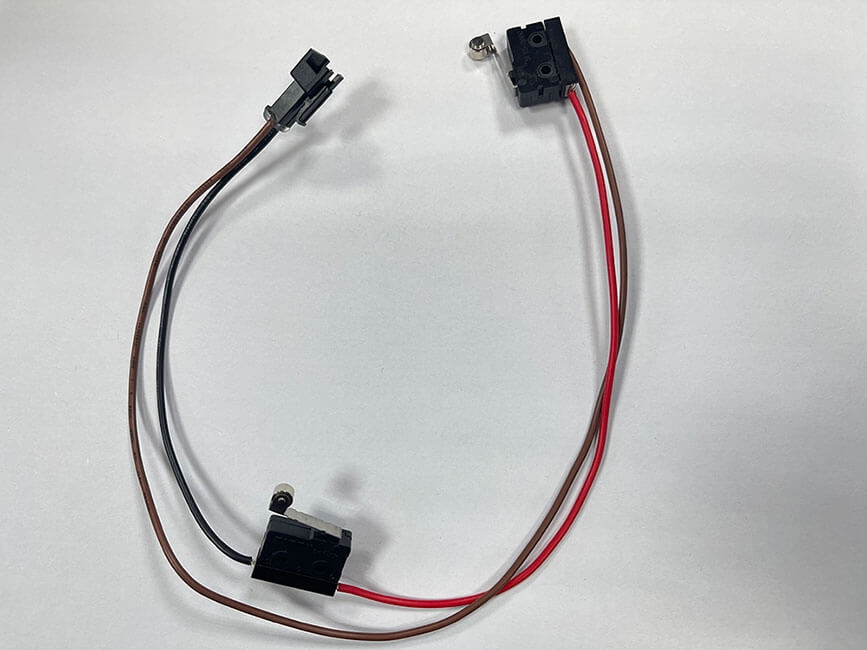

Chang Ming’s Industrial-Grade Solution: Four Advantages Beyond the Standard

- Engineered for Harsh Environments

Based on your specific equipment requirements, we select specialized oil-resistant, high-temperature, and UV-resistant wires, paired with connectors that have a high IP (Ingress Protection) rating for dust and water resistance. This approach neutralizes the impact of environmental factors at the source.

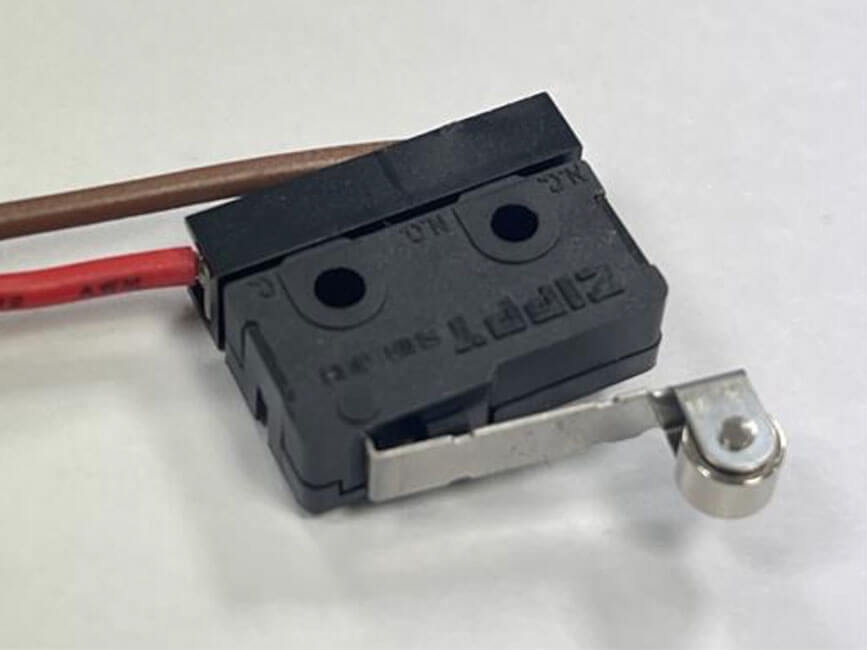

- Absolute Signal Integrity

For high-interference environments, we provide shielded cable solutions that effectively block EMI from motors, inverters, and other equipment. This ensures that the faint signal from an actuated micro switch is received cleanly and accurately by the PLC or controller.

- Durability Tested for Millions of Cycles

Backed by our UL (File No. E318480) and ISO 9001:2015 certified processes, we guarantee that every crimp terminal possesses optimal mechanical strength and electrical properties. Combined with micro switches that have passed severe lifecycle testing, our solutions are built to withstand long-term, high-frequency actuation, significantly reducing your downtime and maintenance costs from component failure.

- Deep, Proven Industrial Expertise

From traditional machine tools to advanced automated warehouse systems, Chang Ming Electronics has provided custom wiring solutions for a wide array of industrial clients. Our experience allows us to help you anticipate potential challenges in the early design stages, proposing optimal harness layouts and integration strategies.

In the wave of Industry 4.0, equipment stability and reliability are core competitive advantages for any business. A high-quality micro switch must be paired with a professional wiring harness of the same quality to achieve 100% performance. Chang Ming Electronics is committed to being your most reliable partner, creating the most robust signal transmission nerves for your industrial equipment.

Contact our industrial applications team today to discuss your equipment needs and let us customize the most durable and reliable micro switch wiring harness solution for you.