Product Manufacturing

Wire Harness Manufacturing and Assembly

At Chan Ming, throughout the production process, we follow strict industry standards. We take all the factors into consideration when producing high-quality product. Working closely with our customers, we will check the design of the harness is efficient before quoting and will use suitable materials for customer requirements. After assuring the final product will meet UL standards or specific requirements/ standards, we move forward into production then.

-

Design

From the sample or drawing provided by our client, we will evaluate the production processes required, design the assembly board for the harness, calculate production and material costs, and provide a quotation to our client.

-

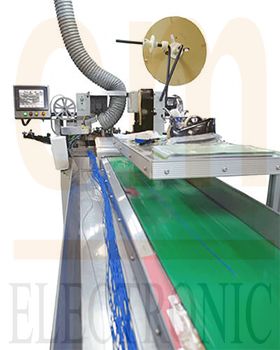

Automated Cutting, Stripping and Connector Crimping

The wire harness will be made up of a number of wires, which may have many different lengths, thickness, connectors, end terminals etc. Cutting these wires to correct lengths, stripping the insulation, and crimping terminals can be all done with automated machinery. This automated process ensures consistent precision and quality of the wire sets to be used for the harness.

-

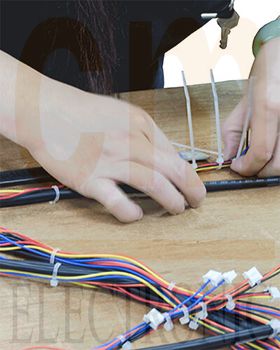

Assembly

Once all component wires have been cut and have connectors attached, they are ready for assembly. Because harnesses for each application will be different, it is usually not practical for them to be assembled automatically, but are more efficiently assembled by hand. All components and wires are arranged in the final assembly area where the harnesses are assembled on form boards. The form board is designed to allow for quick assembly and ensure product consistency.

1. Chan Ming Wire Harness Manufacturing Capabilities

A wire harness is a key component in any electrical application, and its performance and reliability are vital. A thorough understanding of the conditions under which the harness will be used, as well as an understanding of all materials used, will assure that the highest quality harness is designed for each application.

-

Experience

Chan Ming has over 20 years’ experience crafting high-quality, customized wire harnesses and cable assemblies to suit the needs of virtually every industry. As a customized manufacturer, we have the knowledge and skills necessary to deliver reliable, durable and reasonable solutions to all of our customers.

-

Efficiency

We will work with you to assure that your wire harness will efficiently meet the electrical requirements of your application as well as meet the physical requirements for proper performance. In addition to product design, we also take into consideration any governmental regulations or standards that may apply.

-

Production Capacity

We have the ability to manufacture large quantities using cost-effective and lean manufacturing processes. Our wide range of products, combined with our ability to redesign existing products, makes Chan Ming your best choice for harness-needs.

2. Quality Control of Chan Ming Wire Harnesses

At Chan Ming, quality control means two things. First, all our products follow a rigorous "Company Quality Policy," assuring that all products meet strict quality guidelines. Second, we take great concern in assuring that all our customers are completely satisfied with the products and services they receive.

-

SOP Guidelines

Throughout the production process we follow strict SOP management and inspection guidelines, ensuring consistent quality throughout each step of the production process. Some of the quality control measures followed include connector visual inspection, connector pull testing, and electronic signal inspection. Systematic evaluations are regularly made to maintain and improve quality as we strive to completely satisfy our customer's demands.

-

Certifications

Chan Ming is ISO 9001:2015 certified and UL certified. All our assemblies and materials are compliant with RoHS. Also, harnesses/ assemblies can build as components, materials which are compliant with REACH, CSA, PSE e.g. if customer requests.

WIRE / CABLE CUTTING

- Semiautomatic Cutting

- Automatic Cutting

- Fully Automatic Wire Crimping Machine For Cutting, Stripping and Crimping.

-

CPR-ZERO

High volume output - 0.85sec/pc (4200pcs/hr)

Dual-end strip, Dual-end crimp

JNO3S-A1C

High volume output – 0.8sec/pc (4500pcs/hr)

PROCESS

- Jackets Stripping

- Insulation Stripping

- Terminal Crimping

- Conductor Tinning

- Soldering

- Terminal Crimping

ASSEMBLY

- Connector Assembly

- Tie Assembly